Seneca Devices

Samuel Fox is the founder and CEO of Seneca Devices and the lead designer and engineer for the EasyShift and EasyBoost patient repositioning systems. He graduated from Duke University in 2018 with a background in biomedical engineering. While at Duke, he collaborated with the School of Nursing and Engineering to develop the patient repositioning systems for Seneca Devices. Download the Seneca the EasyShift and EasyBoost patient repositioning systems product literature.

“I’ve always loved tinkering with devices and creating new ones. I initially wanted to develop a diagnostic toilet during my undergraduate years but found it very complicated. I started talking to the School of Nursing to understand their problems and realized I could develop a solution for an existing issue. The entrepreneurial path works for me and I knew I wanted to do something like that early on,” said Fox.

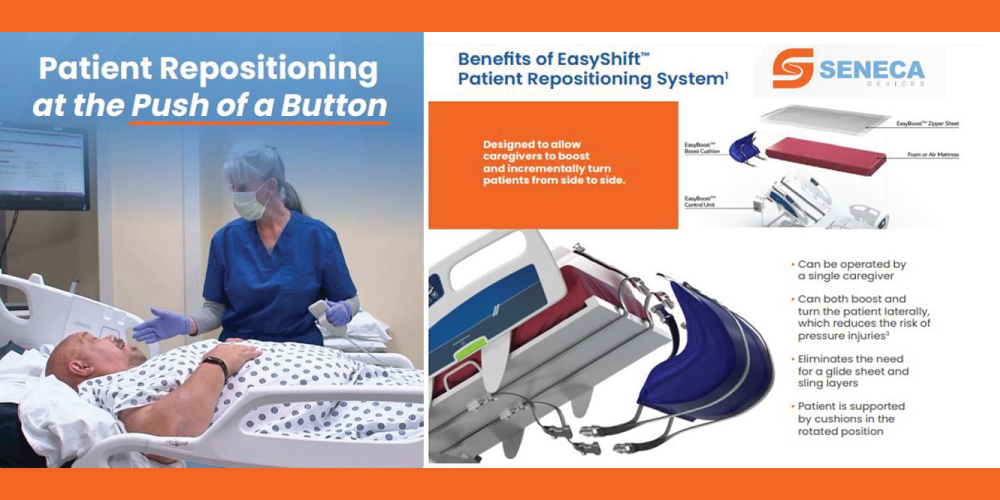

The clinical team identified pulling patients up in bed as a daily task that is both time-consuming and physically strenuous. It often takes 10-20 minutes to gather enough staff and this task is a primary cause of repetitive musculoskeletal strain for caregivers. Seneca designed the EasyShift as a patient repositioning solution that is both high-tech and low-touch. Healthcare professionals can now electronically reposition a patient safely and effectively while maintaining patient dignity, privacy, and safety. When the head-of-bed is elevated, the patient slides down over time due to gravity. This slouched position increases the risk of aspiration and pneumonia, particularly for patients on mechanical ventilation. Poor posture also increases shear force on the sacrum and the risks of skin breakdown.

Fox was personally motivated to develop a solution for a healthcare and caretaker issue. “When I was around 12, my grandmother lived with us for several years, and I saw firsthand the importance of helping her get out of bed and into a wheelchair. This simple act allowed her to go outside and enjoy the garden, which significantly impacted her quality of life,” stated Fox.

After the Seneca team designed and tested early prototypes at the Health Innovation Lab, clinicians suggested that there was a need for a device that could assist to turn the patient side to side, as it often requires a team to do so. Enabling just one caregiver to both turn and boost the patient would promote more frequent repositioning and streamline workflow for sheet changes, skin care, peri care, placement of mobility aids, and more. This would save time for front-line nursing staff and eliminate two leading causes of caregiver musculoskeletal strain.

Seneca designed a mattress overlay with inflatable cushions that gently shifts the patient into bed and turn them side to side. The cushions are inflated by an air pump unit that hangs at the foot of the bed and is controlled by a remote that the caregiver can use at the bedside. The advantages are the ability to boost the patient with the head of the bed at an angle, making it more comfortable for the patient and reducing the risk of gastric reflux and pneumonia.

Product Development at Hangar6

Fox was invited to tour the facility at Hangar6. As part of First Flight Venture Center, Hangar6 supports early stage high-science, high-impact startups in rapidly developing hardware and solving important engineering challenges on their overall path to commercialization. Fox was impressed when he noticed an industrial-strength sewing machine, which they had obtained just two weeks before his visit. “I knew we needed an industrial-strength sewing machine,” Fox said, “and I was using one from Amazon but we needed more to grow as an organization.” In 2020, the Seneca moved its office space to the First Flight Venture Center incubator space and efficiently maximized use of the Hangar6 prototype lab equipment. “Testing prototypes ourselves before contracting out is much faster and more efficient. Doing it in-house allows us to pay only for the materials, which is crucial, especially since working with contract manufacturers or design houses can be extremely expensive, as we experienced in 2020,” said Fox.

Fox says having access to Hangar6’s general-purpose machine shop is invaluable because unexpected needs constantly arise. “We used a Dremel tool, hacksaw and drill to machine the product control box. Having everything in one place and more space to work is much better. We do some 3D printing and occasionally use the lathe and clamps. We use many miscellaneous tools,” stated Fox.

The major value that Hangar6 offers is that it’s an affordable alternative to a full-service design firm, which can be incredibly expensive. Fox commented, “I’ve seen companies spend their entire budget on planning services from these firms, only to receive a few drawings in return. At Hangar6, we can go through three or four design cycles in two weeks, compared to the two to three months it would take to outsource. We use Hangar6 every week. The subscription model is helpful because we can start and stop the service as needed, particularly when beginning or pausing a project.”

By using services provided at Hangar6, Seneca Devices has reduced the cost of manufacturing significantly. “The first prototype version of the product cost $11,000 to manufacture, which was very expensive”, remarked Fox. After some tinkering, the first clinical trial version cost around $4,800 to manufacture. Now, it’s down to $2,200; the slimmed-down version is about $800. “We’ve been working with a contract manufacturer in Wilkesboro North Carolina, and with volume manufacturing, we’ll be able to bring the cost down even further. Our key advantage is that our price point is 30-50 percent less expensive than our competitor’s product,” commented Fox.

Hangar6 created a “Talking Shop” program, an initiative to foster collaboration and knowledge-sharing among innovators and entrepreneurs. This program brings together industry experts, designers, and product developers to discuss challenges, share insights, and explore solutions in product development. Fox volunteered a significant amount of his time to help other innovators, sharing his experiences with Hangar6 and his approach to product development. His efforts have laid the groundwork for other innovators in the state.

Though Fox wasn’t looking for anything in return, his participation in the initiative unexpectedly became a networking opportunity, leading to valuable relationships with potential buyers. “We made an amazing connection with a representative from a nurse educator organization,” said Fox. Meeting potential buyers through Hangar6 programs has been a delightful surprise for him.

Hangar6 helped Seneca Devices create/retain jobs and witnessed significant financial benefits. It achieved $40,000 in cost savings, attracted a substantial $150,000 investment in new processes, and secured a $17,000 investment in other business areas. The organization avoided $25,000 in unnecessary investments.

Although Seneca Devices is currently focused on the hospital market, they strive to provide solutions to the home care market. “The market demand for this kind of equipment is significant and there is much opportunity for innovation in this space. The need for such devices is clear and seems to fit our capabilities and mission,” said Fox.