Hydration for the Future

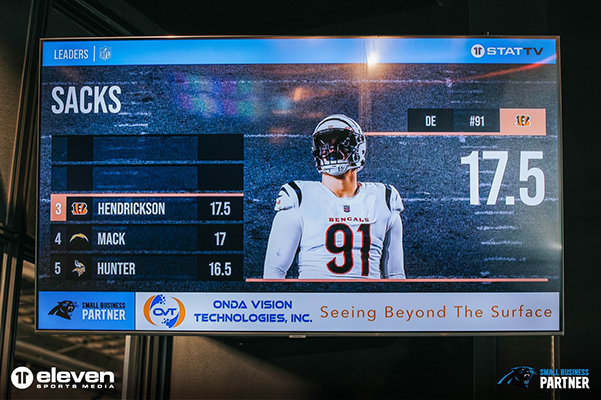

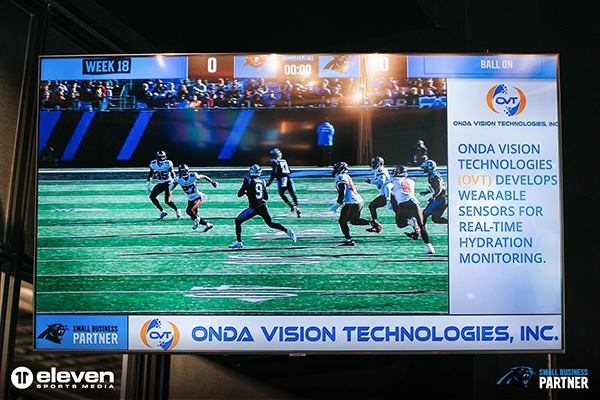

Onda Vision Technologies produces wearable sensors for real-time hydration monitoring. The technology targets populations at risk of dehydration, such as athletes and individuals under heat or disease stress. Providing data-driven insights into hydration levels enhances safety, improves performance, and reduces medical costs. “Every year, we hear stories of college and high school athletes practicing and competing in hot, humid conditions, some of whom pass out or are rushed to the hospital, risking fatalities or organ damage. Our goal is to provide an early alert to prevent these situations by focusing on team-based sports and working directly with colleges and high schools to deliver our solution”, stated Onda Vision Technologies founder Dr. William Renyolds.

Reynolds began his entrepreneurial journey by attending a “How to Start a Business in North Carolina” seminar at the NC Small Business Technology Development Center (SBTDC). He brought his ideas to life through connections while participating in programs designed to support entrepreneurs, technology, manufacturing, and small businesses in North Carolina.

Reynolds began his entrepreneurial journey by attending a “How to Start a Business in North Carolina” seminar at the NC Small Business Technology Development Center (SBTDC). He brought his ideas to life through connections while participating in programs designed to support entrepreneurs, technology, manufacturing, and small businesses in North Carolina.

“Despite my extensive experience in Research and Development, I felt unfulfilled, so I decided to turn my research idea into a business plan.,” said Reynolds. Before he learned about the opportunity to partner with NC State University Assist Center to develop his hydration technology, Reynolds had over 20 years of experience in corporate and governmental research and development in algorithm and software development.

Through the North Carolina Small Business and Technology Center (SBTDC), he was introduced to connections at NC State University, where he was told there was a use case for his technology and informed about the USDA Hydration Small Business Innovation Research Grant. “They invited me to develop my business under the umbrella of an NC State startup company. I thought there had to be a catch, but all I had to pay was the license and royalty fees associated with the grant. I accepted the offer and I’ve been running ever since.”

North Carolina Defense Manufacturing Community Support Program

Reynolds learned about the North Carolina Defense Manufacturing Community Support Program (DMCSP) grant that supported his participation in the Propeller pre-accelerator program offered by North Carolina Manufacturing Extension Partnership (NCMEP) partner First Flight Venture Center/Hangar6.

The First Flight Venture Center/Hangar6 Propeller pre-accelerator program serves early-stage science and technology innovators by helping them bridge the gap between a brilliant idea and the business value it represents. It is based on the Wendy Kennedy Institute (WKI) methodology but tailored to science and technology-focused companies. It is an entrepreneurial design thinking program that helps founders and entrepreneurs determine whether there is sufficient value to pursue a product or service idea. The program allows entrepreneurs to identify potential markets, develop a path to market strategy, and learn how to communicate the value of their ideas to early stakeholders and adopters. Over six weeks of instruction, Propeller enables innovators to utilize the tools provided and peer interaction to consider angles from the business problem, customer value, and competitive edge–resulting in a clear understanding of the business direction and value of their idea and how to present this value in an investor-ready pitch.

The North Carolina DMCSP project aims to strengthen defense-advanced textiles/wearables manufacturing capabilities through an industrial production ecosystem that melds cybersecurity, artificial intelligence, microelectronics, biotechnology, textiles, and additive manufacturing. The North Carolina DMCSP Consortium involves over 20 entities across the state to build on existing textile manufacturing collaborations to establish a best-in-class innovation ecosystem for the research, development, and production of smart textiles and wearable devices in support of warfighter health and performance.

The North Carolina DMCSP project aims to strengthen defense-advanced textiles/wearables manufacturing capabilities through an industrial production ecosystem that melds cybersecurity, artificial intelligence, microelectronics, biotechnology, textiles, and additive manufacturing. The North Carolina DMCSP Consortium involves over 20 entities across the state to build on existing textile manufacturing collaborations to establish a best-in-class innovation ecosystem for the research, development, and production of smart textiles and wearable devices in support of warfighter health and performance.

Reynolds stressed the importance of collaboration, saying those alliances were essential in advancing his organization, “The combined support from NCMEP and Hangar6 has been instrumental in the growth and success of Onda Vision Technologies. Their assistance in technical improvement, technology adoption, market expansion and research and development has enabled the company to grow.”

USDA Hydration Small Business Innovation Research Grant

While working on their wearable prototype, Onda Vision needed a place for initial testing and proofs of concept to be considered for the USDA Hydration Small Business Innovation Research (SBIR) grant; Reynolds found that at Hangar 6. “Hangar 6 helped cut some pieces and provided valuable design advice and support, offering services through their program. This was a huge relief as it meant I didn’t have to buy expensive equipment or repeatedly return to NC State. Hangar 6 gave me another option to develop and test my idea,” said Reynolds.

As a recipient of the SBIR grant, Reynolds applied his technology to address hydration needs in agricultural and rural settings. The program, funded by the United States Department of Agriculture (USDA), aims to stimulate technological advancements and entrepreneurial ventures to enhance water management, improve hydration techniques for crops and livestock and ensure sustainable water use in agricultural practices. The program encourages small businesses to engage in research and development projects. It paves the way for new methods and technologies for efficient water usage, irrigation systems, soil moisture monitoring, and hydration-related challenges.

“From a business standpoint, the USDA SBIR proposal was a godsend, especially since this was our second time applying. At the time, I was in the middle of my review for my NSF Phase Two program. The NSF wanted to see cash reserves in our financials without explicitly stating it because we were undergoing an audit. It was almost Christmas Eve, and I was stressed about how to raise $50,000. I considered raising a family and friends using a SAFE (Simple Agreement for Future Equity). Then, I received a call from the USDA congratulating us on being awarded Phase One funding. The Hangar6 Propeller pre-accelerator program helped us get it,” stated Reynolds.

The USDA funding filled a critical technical gap, enabling Onda Vision to produce the core sensor for their hydration product. It provided the time and resources needed to fully integrate the last core piece from the university as we moved toward market readiness.

Hangar6 helped Onda Vision Technologies create/retain a job and witnessed significant financial benefits. It achieved $10,000 in cost savings, attracted a substantial $972,000 investment in new processes, and secured a $50,000 investment in other business areas. This success story is a testament to North Carolina’s commitment to fostering growth and innovation in small businesses.