2024 Rankings: Best States for Manufacturing

- North Carolina

- South Carolina

- Tennessee

- Indiana

- Kentucky

The 2024 rankings align closely with previous years, where states like North Carolina, South Carolina, and Tennessee consistently rank at the top. Notably, North Carolina narrowly edged out South Carolina in 2024, illustrating the tough decisions manufacturing companies often face when comparing these high-performing regions. In 2023 and 2022, North Carolina landed in the number two position.

Visit the Site Selection Group webpage to read the full article.

Manufacturing in North Carolina

North Carolina’s strategic advantages, economic policies, and favorable demographics contribute to its consistent top-tier status.

Key Metrics of Manufacturing in North Carolina

- GDP Contribution: Manufacturing contributes over $100 billion annually to the state’s economy.

- Exports: Products manufactured in North Carolina reach markets worldwide, with machinery, chemicals, and vehicles leading the way.

- Employment Impact: The manufacturing sector employs over 450,000 workers, accounting for a significant portion of the state’s workforce.

Skilled Workforce and Labor Market

- Strong Educational Institutions: Home to renowned universities like Duke, UNC Chapel Hill, and NC State University, and a strong Community College System, North Carolina excels in workforce development. These institutions collaborate with industries to provide relevant training, particularly in advanced manufacturing and technology.

- Demographic Alignment: The state boasts a growing population with a labor force well-suited for manufacturing, logistics, and engineering roles.

- Competitive Labor Costs: Labor costs are generally lower than those in many competing states, while the quality of the workforce remains high.

Business-Friendly Environment

- Attractive Tax Climate: North Carolina maintains one of the lowest corporate income tax rates in the U.S., currently at 2.5%.

- Pro-Business Policies: State and local governments actively offer economic incentives, including grants and tax breaks, to attract new investments.

- Regulatory Environment: Streamlined and predictable regulations make it easier for businesses to set up operations.

Logistics and Geographic Advantage and Supply Chain Synergies

- Strategic Location: Positioned midway along the East Coast, North Carolina provides easy access to major consumer and industrial markets in the U.S.

- Robust Infrastructure: The state features:

- Well-developed interstate highways connecting major markets.

- Two deepwater ports (Wilmington and Morehead City) for international shipping.

- A strong rail network and proximity to intermodal facilities.

- Major airports, including Charlotte Douglas International Airport, a key cargo hub.

- Speed to Market: The combination of infrastructure and location enables rapid delivery times to domestic and international markets.

- Exports: Products manufactured in North Carolina reach markets worldwide, with machinery, chemicals, and vehicles leading the way.

- Major manufacturing hubs include the Charlotte region, Research Triangle Park (RTP), Greensboro/Winston-Salem (Piedmont Triad), and Eastern NC (food processing and textiles). Industry clusters promote collaboration and innovation.

- Supply Chain Synergies: A broad industrial base and integrated networks allow for localized sourcing, reducing costs and lead times. Many manufacturers benefit from robust local supply chains, reducing reliance on overseas imports.

Cost Competitiveness

- Operating Costs: North Carolina offers lower operating costs than other manufacturing hubs. Key contributors include:

- Affordable real estate and facility costs.

- Low utility rates, particularly for electricity, are crucial for manufacturing operations.

- The overall cost of living remains below the national average, which helps keep wage inflation in check.

Diverse Industry Ecosystem with a Proven Track Record of Investment

- Established Manufacturing Base: Industries such as automotive, aerospace, pharmaceuticals, and food processing thrive in the state.

- Automotive and Transportation: Toyota, VinFast, and Daimler Trucks North America are major players. There is a strong focus on electric vehicles (EVs) and advanced automotive components.

- Aerospace and Defense: North Carolina is home to companies like GE Aviation and HondaJet, which produce engines, avionics, and private aircraft—growing investments in defense-related manufacturing and R&D.

- Biotechnology and Pharmaceuticals: The Research Triangle Park (RTP) hosts major pharmaceutical manufacturers like Pfizer, Novo Nordisk, and Biogen—advanced manufacturing of biopharmaceuticals and medical devices.

- Food and Beverage Processing: North Carolina is a leader in food and beverage manufacturing, hosting companies such as PepsiCo, Campbell Soup Company, and Smithfield Foods. Access to abundant agricultural resources supports the supply chain.

- Advanced Materials and Electronics: The manufacturing of semiconductors, nanotechnology, and composite materials is growing, and it is supported by R&D at local universities. Companies like Cree (Wolfspeed) lead the production of silicon carbide and LEDs. North Carolina has embraced high-tech manufacturing, supported by innovation centers and R&D partnerships.

North Carolina’s Quality of Life

- Affordable Living: A moderate cost of living makes North Carolina attractive for employees and their families.

- Natural and Cultural Appeal: Its access to mountains and beaches and vibrant cultural and recreational opportunities enhance its appeal as a relocation destination for companies and workers alike.

The North Carolina Manufacturing Extension Partnership (NCMEP)

The North Carolina Manufacturing Extension Partnership (NCMEP) provides manufacturing extension services that enhance North Carolina-based small and medium-sized manufacturing firms’ productivity, innovative capacity, and technological performance. NCMEP is the official state affiliate of the NIST MEP National Network.

NCMEP is administered by NC State University Industry Expansion Solutions (IES) and partners with the North Carolina Community College System, Customized Training; the Economic Development Partnership of NC (EDPNC); The Polymers Center of Excellence; the Manufacturing Solutions Center; First Flight Venture Center/Hangar6; UNC Charlotte Industrial Solutions Lab; and NC State University Wilson College of Textiles.

NCMEP partners provide North Carolina manufacturers support with:

- Advanced Manufacturing and Technology Adoption and Deployment

- Business Growth, Innovation and Marketing

- Cybersecurity Strategies

- Defense Industry Initiatives

- Entrepreneurial Development

- Existing Business Expansion

- Industrial and Systems Engineering

- International Trade

- Market Research

- Process Optimization

- Product Development and Testing

- Small Business and Startup Counseling

- Supply Chain Optimization and Supplier Matching

- Workforce, Leadership and Organizational Development

- Workplace Health and Safety and OSHA Training

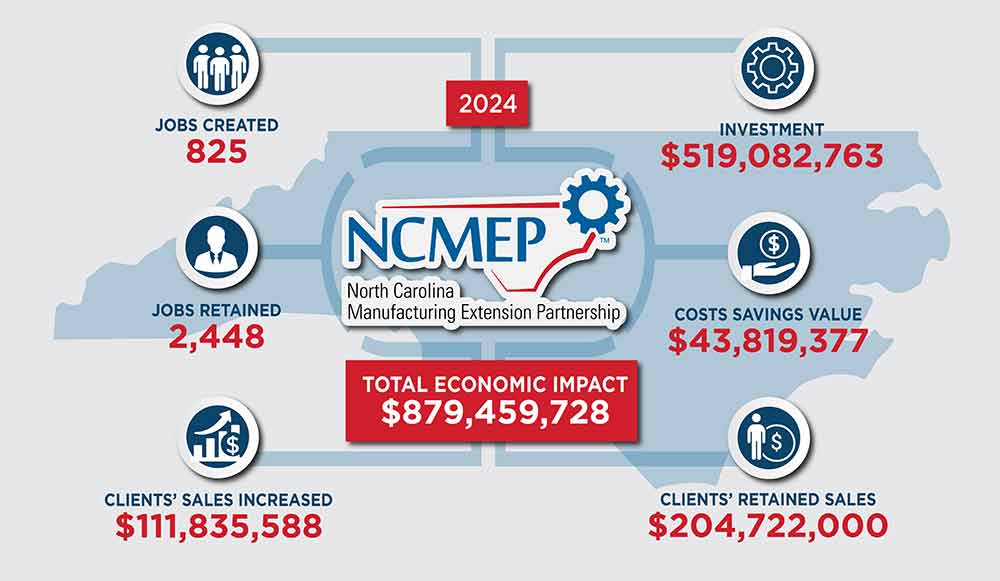

NCMEP delivers significant economic impact to the state manufacturing industry through outreach and services.

NCMEP collaborated with the North Carolina Department of Commerce to produce a comprehensive analysis and strategic guide titled “Best Practice for Growing Manufacturing in North Carolina—Essentials for Success in Industry 4.0.” The report identifies critical areas for development, including the adoption of advanced “Industry 4.0” technologies, workforce enhancement, support for small manufacturers and strengthening of supply chains. The collaborative effort underscores a commitment to ensuring North Carolina remains at the forefront of manufacturing excellence and innovation.

NCMEP collaborated with the North Carolina Department of Commerce to produce a comprehensive analysis and strategic guide titled “Best Practice for Growing Manufacturing in North Carolina—Essentials for Success in Industry 4.0.” The report identifies critical areas for development, including the adoption of advanced “Industry 4.0” technologies, workforce enhancement, support for small manufacturers and strengthening of supply chains. The collaborative effort underscores a commitment to ensuring North Carolina remains at the forefront of manufacturing excellence and innovation.

Manufacturing is a cornerstone of North Carolina’s economy, offering a pivotal platform for innovation, employment, and economic development. However, with rapidly evolving global markets and technological advancements, strategic action is critical to ensure the sector not only sustains but thrives. The report presents a forward-looking strategy for enhancing North Carolina’s manufacturing capabilities.

About Site Selection Group

Site Selection Group is a full-service location advisory, economic incentives, and real estate services firm specializing in helping manufacturing companies find the most competitive locations. Its process employs a top-down, data-driven approach to site selection, leveraging advanced analytics and filters to pinpoint ideal options.

A key proprietary tool in this process is GeoCision®, a weighted model designed to score and rank candidate locations based on critical site selection variables.