North Carolina Manufacturing Extension Partnership (NCMEP) network’s partner, The Polymers Center of Excellence has supported and sustained companies in the polymers industry since 1998. With a successful 25 year history, it remains the one-stop-shop serving clients nationwide with training, materials science, and product development of polymers such as nylons, olefins, polyesters, and various engineering resins. Recently it has been working with companies who are developing degradable compounds that might address some of the disposal issues associated with packaging materials.

Initially named the Polymer Extension Program (PEP), the center was established to support the expanding plastics industry in North Carolina. Led by Paul Cowgill, Joe Bennett, and Charles Case, the center was incorporated in 1998 under the leadership of its first Director, Robert L. van Brederode. In 2000, the center settled into its current location at 8900 Research Drive in Charlotte, North Carolina. Over the years, under the leadership of Dennis L. Hayford, the center expanded its equipment and services beyond simple training and into extrusion processes. Because the center is committed to supporting and encouraging the polymers industry in North Carolina, their expertise, equipment, technology, and training programs expanded to meet the needs of that growing market.

Leading The Polymer Center since 2015 is director Philip Shoemaker. Shoemaker has a long history in the manufacturing industry. He started his career in a PVC compounding plant in 1982, working in multiple positions and gaining valuable knowledge about polymers and the equipment needed to work with them. Shoemaker reflected on his transition to The Polymers Center, “I saw an organization that had wonderful potential ahead of it and given my interest in the history of the science and technology of the plastics industry, it seemed like a nice fit for what I’ve been doing over the last 40 years.”

The Polymers Center is one of NCMEP’s longest-standing partners. “The relationship between Polymers Center and the wider NCMEP network is mutually beneficial. At the Polymers Center, we see ourselves as a piece of a bigger organization devoted to the development and success of manufacturing in North Carolina,” stated Shoemaker.

Training at The Polymers Center

From film and sheet extrusion to injection molding, to design and testing, The Center fosters growth and innovation. Over the past 25 years, it has expanded its classes by teaming up with industry experts to bring the latest polymer training classes to the state of North Carolina, the Southeast and the United States. The Center can customize its training classes to focus on specific problem-solving skills, processes, equipment operations and polymers themselves.

From film and sheet extrusion to injection molding, to design and testing, The Center fosters growth and innovation. Over the past 25 years, it has expanded its classes by teaming up with industry experts to bring the latest polymer training classes to the state of North Carolina, the Southeast and the United States. The Center can customize its training classes to focus on specific problem-solving skills, processes, equipment operations and polymers themselves.

Shoemaker recalls, “An experienced engineer called us and said, ‘I was just informed that the injection molding machine that’s sitting on our dock, which I never even heard of before, is now going to be my job to run. I have no knowledge of molding. Can you guys help me?’ We made arrangements to go to his plant after they got the machine installed and we trained him and others, which enabled him to successfully start up and operate their new molder. We normally customize our classes to meet the needs of any given organization, especially those seeking extrusion or injection molding expertise.”

View current classes or download a course flyer. To schedule training onsite at your facility or to customize training, contact Phil Shoemaker at 704.602.4100.

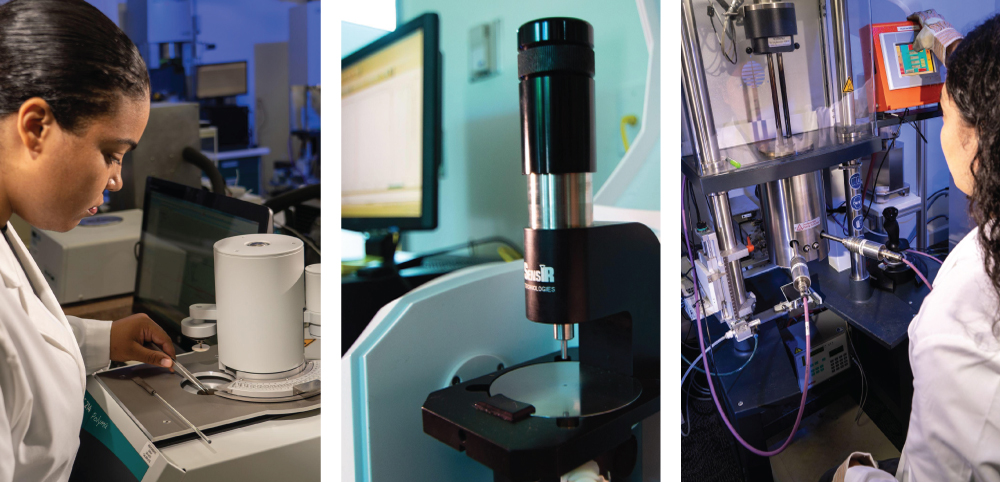

Compound Development and Testing

The Polymers Center is also involved in engineering endeavors. It has expanded its compounding lines, as well as enhanced its analytical capabilities. Shoemaker shared, “When I arrived here in 2015, we had two extruders—one quite service-weary and a 50 mm Leistritz twin. We now have four lines, all of which are twins from Leistritz. Together they enable us to offer masterbatch processing and extrusion, custom compounding, product development trials, low and high shear blending, and reactive extrusion.”

“We’ve also added three molding machines, all gen 4s, one each from Shibaura, Engel, and Arburg. We’ve made several additions to the lab, too numerous to detail, but a vibratory viscometer has been the latest addition. It allows us to determine viscosity without resorting to the capillary rheometer, greatly improving our testing capabilities.”

Shoemaker credits the success of The Polymers Center to flexibility and adaptation. “Just as in biological evolution, the most successful companies are those that rapidly adapt to the needs in the marketplace. As we started fulfilling those needs, and as we became increasingly familiar with them, we could tailor our offerings more accurately.” Shoemaker continued, “For example, there are other testing services and there are other compounding services. But only at The Center can a compound be developed, molded, and analyzed all at one location. This quality is what makes us unique.”

Meeting Room and Injection Molding Lab Rentals

Located in the Charlotte, North Carolina area, The Polymers Center offers a 44-seat capacity classroom with an adjacent full kitchen available for rent for corporate or business meetings. A projector and refreshments can be arranged for your convenience. In addition, an injection molding lab that includes 3 molding machines, a projector and assistance from a Polymers Center injection molding operator, is also available for a rental fee. Time on the machines may also be reserved separately. Contact Beverly Jarrell at 704.602.4127 or for availability.

Molding the Future

As for the future of The Polymers Center, Shoemaker continues to explore new services. “I firmly believe that The Polymers Center can become a clearinghouse for information related to plastics recycling. This fall, we will have an event on recovery methods which I hope is the start of many such seminars. These seminars will help folks look at plastics differently and perhaps provide a path forward that isn’t so politicized.”

To learn more about The Polymers Center, visit polymers-center.org.